Luis Seabra is an exacting winemaker, whose implicit philosophy is “if you’re going to do it, you might as well do it right.” He walks with a gait best described as dromedary: in the most flattering way, something about him reminds you of a camel. And he carries himself with ponderous and brooding energy — Deniro, Rocky I Stallone — calm, collected, and reserved. As you get to know him, you find a raucous sense of humor, intolerance for idiocy, and a bottomless knowledge and respect for food, wine, and vine.

I met Luis at a local wine bar in Porto, April of 2021. Then, in early June I called and asked to go see his winery. He was moving from the winery of nine years into a new facility, and scrambling to make sure it would be ready before the first grapes came in. At that point, it was an industrial shell: rough concrete flooring, walls, and a roof. Pigeons flapping in the rafters and a jackhammer working the concrete floor. It held no tanks, no barrels, no wine, or windows — only enough electricity for construction crews to work.

I shadowed Luis as he spoke in Portuguese to the workers, pulling out and drawing on plans, measuring the kitchen space, marking out utilities, and taking a phone call every 10 minutes. Flooring, electrical, kitchen equipment, lab layout, bathroom finishes, tank location, barrel storage, temperature control: it seemed he was inhabiting the already-complete winery in his mind, down to fine detail, and doing his damnedest to make sure the work crews could bring reality along to match.

Approaching Harvest

In July, I called Luis to see about work on his team as a harvest intern. He asked, quickly, “are you prepared to suffer?” I knew from two friends who had worked with him in years past that “suffering” was not a jest—hard work, long hours, little sleep. I said “not unreasonably so,” and it seemed to pass muster. We arranged the rest. In broad strokes, I would provide my labor and suffering in service of harvest winemaking, and Luis would provide lodging, food, wine with every meal, and full access to learn and perform each aspect of winery work.

I joined Luis, his wife Natalie, his two full-time staff members, and four other interns (Pedro, Gonçalo, António, and Gaioz) on the harvest team. We lived in a rented harvest compound in Sao João da Pesqueira, a small town in the Cima Corgo region of the Douro Valley. Natalie oversaw general education and mannering of interns, well-being and well-fedness of the crew, quality of the sorting table work, maintenance of clothes, an ongoing supply of wine for daily tastings, and the flow of harvest work wherever it needed a push. All of this she quarterbacked from the driver’s seat of a comically oversized white Mazda van. It was distinguished by its lack of power steering, temperamental windshield wipers, dim headlights, and an immobile drivers’-side window, always partially open. From what I gather, it was a riot to drive in the rain.

On August 28th, it was a stunning train ride through the Douro river landscape to Régua. Luis picked me up from the train station and, close to lunch already, we gathered the team at the winery and went to the harvest house for a three-course lunch and three blind bottles of wine to think through. Two hours later, my work began. The next six weeks was a hands-on course in the practical, theoretical, and philosophical aspects of winemaking. From this broad base, a slim set of maxims emerged between us, “rules” about wine and work that propagated themselves through repetition.

Rule 1: ”Don’t Break the Glass”

The first one that I learned and the first one that I broke was simple: “Don’t break the glass.” Luis had multiple sets of high-quality glassware, and they were our twice-daily companions. Every day after dinner, Luis would hand-wash glasses and set them to dry. Most nights, he would hand dry and polish them immediately, so that we were prepared for tomorrow. On my third day I picked up a cloth to help with the drying operation and Luis eyed me, skeptically.

“Careful. I can handle it. They’re delicate.”

I spent a year in fine dining, half of that on the bar, polishing a few thousand glasses without incident. I figured I could indeed be careful. I picked up the glass and began to apply the cloth.

Luis, slowly, with emphasis: “Don’t. Break. The Glass.”

I nodded, dried and polished the first glass without issue, noticing that yes, these really were quite delicate glasses. I promptly crushed the bowl of the next glass into the polishing cloth.

A look. “ … What did I just tell you?”

That act was a misdemeanor, no felony crime; I would go on to polish a great many of glasses, with rave critical review. (It would not stop Luis from trotting out the Rule One reminder, “Whatever you do…”, each time I got near a glass.) The glassware, large and delicate, could be replaced, but it represented the longer arc of our work. Everything we were doing led back to the glass. And the rule set a tone for the simple kind of care and attention that was needed for all of our work in the winery.

Rule 2: ”Don’t Fuck Up The Wine”

The prime directive was much more fundamental, and far reaching in its implications. Whatever you do, “don’t fuck up the wine.” We came to see how this rule was forever applicable from the moment a box of grapes entered the winery: in the sorting and selection of grapes; in the care for equipment used to process and transport every cluster; in attentive measurement and tracking of each fermentations’ progress; and at every step of operations to punch down, pump over, rack, transfer, or sample any of the wine in the house.

Grapes arrived in the winery by the truckload, each truck carrying 120 to 240 twenty-five-kilogram boxes. We knew the growers and the vineyards already: Luis worked with around 30 growers this year, and in the mornings a small team of us would drive out to visit a number of their vineyards, running up and down the rows of vine, each selecting 33 grapes (if there were three of us) or 50 grapes (if two), gathering a representative sample that we’d bag, label, and eventually take to the lab for analysis. The process is called maturation control, and along with the qualitative state and subjective taste of the grapes, Luis would receive from the lab a fairly accurate read of the total acidity, pH, and potential alcohol of the grapes in the vineyard. The vineyards were anywhere from five minutes to a few hours drive away. I was amazed that, except for one wayward safari into the veld (you’ll be surprised at the range of landscapes Douro has to offer,) Luis brought us safely to each and every vineyard by memory alone.

When a vineyard was ready for harvest, on the day before, Luis would send our driver with a predetermined number of empty boxes to be filled by the grower’s harvest team. After the work of morning maturation control trips and winery operations, we would prepare “the line” for reception. Setting the line entailed properly placing and connecting each machine so that boxes full of grapes can be emptied into one end, and the vibrated, sorted, destemmed-or-crushed-or-whole clusters would come out the other side, fed into the press (white grapes), or lifted into the vessel prepared for fermentation (red grapes). After a few weeks, our team could set up and point the line to any tank in the house in about half an hour, arranged just-so to allow for a quick switch to the next vessel, when this one was full.

Growers’ teams would harvest from the early morning onward, grapes often arriving well after we’d prepared the line to receive them. The level of effort for processing grapes depended on the condition of the vineyard: growers’ own teams were harvesting, and grapes were paid for by the kilogram, so everything was collected from the vine without much pre-selection in the vineyard. For the best-condition red vineyards, we might only need one or two people on the sorting table, picking out raisins and any errant leaves or bits of cane. For the worst-condition whites, after the late rains in this long and cool season, our sorting table required all hands on deck: rot, mold, mildew, and oidium were not scarce. The mandate—don’t fuck up the wine—was not to allow any bad grape to pass. Pick up a cluster, strip off the bad grapes or take the whole thing out, dump into the discard rail, return any good grapes, and repeat. Fast.

Where 200 boxes of grapes in good condition might take an hour to process, limited by the strength of the lucky box-flipper, that same quantity of grapes in bad condition could take three to four hours of intensive sorting. If hands moved slowly on the table, Luis would yell without restraint: “Get all the rot! Get all the rot!"

When it comes to rot or raisins, it's important not to mistake the condition of the grapes from a given vineyard for the quality of those grapes. One of our most difficult sorting tables was that of Luis’ top-tier Douro white, the Xisto Cru—“raw schist”—a high-altitude vineyard not spared from rot by the early-September weather.

When grapes were in and through the line, one step always remained. Be it 9pm or 4am, we were going to clean everything. Every machine and surface that touched grape would be purified with a five-step ritual: a rinse with water; a cleaning spray and scrub with a strong alkaline solution; a rinse with water; a disinfecting rinse with a light citric acid solution; a final rinse with water. The machines, especially the tall “giraffe,” an inclined belt elevator that lifted grapes into the large tanks, were not designed for easy cleaning. Each of the five to seven machines on the day’s line (depending on red, white, or both) might take 45 minutes to be cleaned. Each box, too, hundreds of them, would be cleaned and disinfected with a sulfur solution, then stacked twenty-high near the back loading dock, ready to go out to the next vineyard. The press, thankfully, would run late into the night, and one of us would empty and clean it promptly the next morning, a two- or three-hour job, depending on who did the work.

Every surface that could hold the smallest pip or spot of skin or drop of juice is a potential site for contamination. Just a bit of grape sugar exposed to the open air would do the trick: bacteria, mold, anything else floating around could get its first foothold on an unclean surface, beginning an invisible assault on the second rule.

Rule 3: ”Wine is About Logistics”

The logistical-operational nature of all this processing and cleaning framed an ever-constraining aspect of the work: the winery is a site for the manipulation, processing, movement, and storage of massive quantities of grape-stuffs. Their solids, their juice, the resulting wine. Decisions are bounded by straightforward logistical concern—which vineyards are ready, and how many grapes do we have coming in? How much space is available for fermentation? Which kind of space is available?

I came in with a romantic view of the winemaker following their artistic whim, working from divine inspiration in their choice of vessels, materials, and winemaking technique. If you can do whatever you like… why not try… everything? The notion was quickly grounded by a frank discussion of the costs for tank, barrel, and machine.

I felt the logistics viscerally and physically starting on September 17, 2021. It was the first day of the storm, a whole hellish week of heavy lifting and extremely limited sleep. It started with the special picking crates that we lifted down from truck to staging, up from staging to the sorting table.

Luis has about a thousand of these boxes for grapes, stamped with LSV for easy owner-identification. They can be nested into a standard empty stack, and have an offset stacking that rests one box on the inner rim of the one below, preventing the contents of lower boxes from being crushed too soon. In the winery, at the end of any day, you could look toward the back loading dock, count up the twenty-stacks of empty boxes, and get a rough idea of what was coming tomorrow. Say there are about 600 boxes gone from the stack, we did 240 today that aren’t washed yet… so there are 360 boxes out for tomorrow. Maybe two or three truckloads, if nothing changes.

On September 16th I looked back and didn’t see any boxes, anywhere. Everything was out of the house. I did not immediately catch the implications: it meant that on the next day we would process the maximum number of grapes possible. Given the limiting factor of harvest-box-quantity, about one thousand boxes would come in, each holding 25 kilograms, often packed higher with a few kilograms extra. (Somehow many of those boxes that I lifted were clearly in the 35 to 40 kilogram range.) Trucks started coming in the afternoon, and we could barely offload the boxes from one before the next rolled up. Finally, by 7pm, we had all the grapes and boxes in the winery. Two minutes into a celebratory beer before starting the line, we heard the rumbling of what sounded impossibly like a delivery truck. Luis had borrowed boxes from another grower so he could harvest one more ready-to-pick vineyard. Spirits dropped and the beer did, too, while we pulled the next 150 boxes down from stacks in the truck. Bedtime was 8am that night.

But the operational flow was starting to reveal itself. When the vineyard is ready, we harvest the grapes. How much we can harvest is limited by how many boxes we have for that vineyard to collect the grapes. How quickly we process the grapes is limited by their condition and, for whites, the status of the press. Where we put the grapes after processing, and how we process them, is limited by our available space in tank and barrel.

At one point I asked Luis why we were now crushing and de-stemming grapes I thought he had meant to leave as whole clusters. The answer, of course, was “wine is about logistics.” We were running out of space, and had to try and fit this whole vineyard into that tank; destemming and light crushing would reduce the total volume they would occupy. Then we could move to the next truckload (a different vineyard) and point the line to another vessel, keeping the fermentation running per-parcel.

Of course, reception and processing of grapes is just the beginning of the larger scope of winemaking. The fundamental unit of work in the winery, once we got past the dreaded box-count and then truck-count, was fermentation. Each distinct batch of grapes put into a tank together were identified with the code of their initial reception tank, and the sequenced number of their fermentation batch. These were correlated to the loading bills and maturation control results from specific vineyards(s).

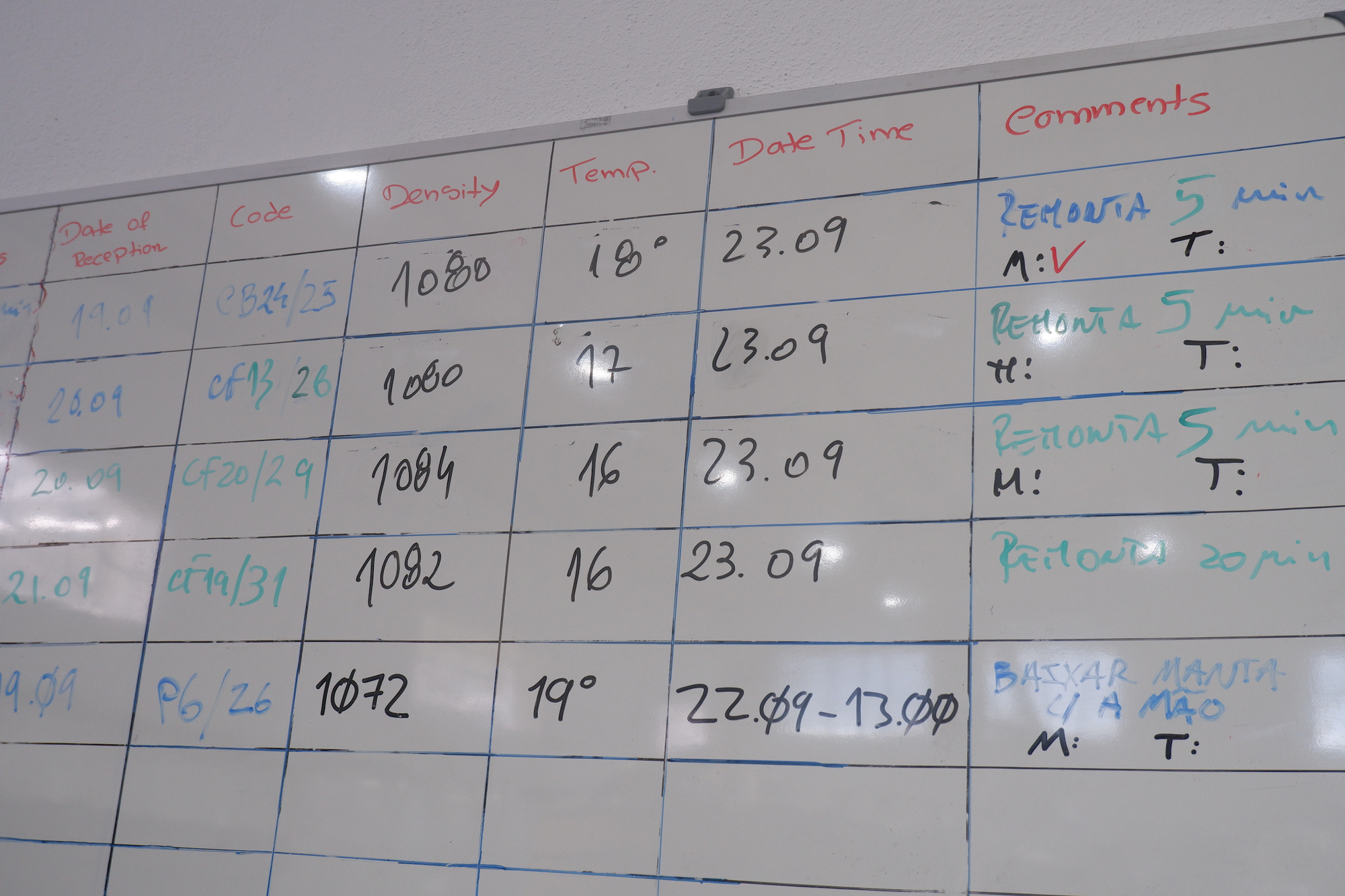

This year, our first fermentation was C12/1, and the last D6/71: seventy-one different batches of grapes were vinified and tracked. The fermentation code, CF19/31 for example, meant that we received the grapes of our 31st fermentation in cuvee fermentaçao (fermentation tank) CF19. This code would follow the fermentation as it was pressed, transferred, divided into barrels, or (a tracking nightmare) partially blended into other tanks. Each fermentation was monitored every day for its density and temperature, recorded to understand progress of fermentation objectively, comparatively to the others in the winery, and also for the historical record to understand each vineyard’s performance year over year.

I came to see, underneath all the operations, that there is a craft in how the winemaker sets up the larger system that produces quality wines, given the physical, logistical, and financial constraints on hand. There is art in aligning those constraints with the winemaker’s taste and philosophy, to ensure that a certain kind of spirit can live in the wine coming out of the winery. And there is art in the specific sequence of choices made for each vineyard, for every fermentation and its hermit-crab life in the winery, from tank to tank to barrel to bottle. It felt like Luis could see the work across all its levels of scale: from the broad interconnected arc of the entire logistical operation, cascading down into a discrete and ruthless attention to each choice at every step along the way.

Wine is about logistics, but it detracts nothing from the winemaker’s art.

Rule 4: Eat Well; Drink Blind

For Luis, the love of food and wine that guides his work was never stated aloud, it was simply made plain by daily practice. He and Natalie brought their entire, well-appointed kitchen to our harvest house: plates, serving dishes, cutlery, enameled cast-iron cookware, sauté pans, baking dishes, Japanese knives, hand tools, pantry stock, grain, rice, dried legumes, spices. And multiple sets of fine, intact glassware.

We ate alarmingly well, always as a team, outside under the shade with sun and heat, in the house with rain or cold. Natalie cooked for us most days, handling lunch and leaving from the winery ahead of our team to prepare dinner. Luis put on an apron as sous-chef when we returned, or as chef for some of the more extravagant features: roasted bone marrow, a range of delicious Portuguese seafoods, massive whole-roasted fish, pan-seared duck breasts, and so on. Guests—family, friends, importers, chefs, winemakers, restaurant owners—came through often enough, and those meals proved long and interesting. Natalie said she was running a six-week popup restaurant for ten, lunch and dinner, but the operation seemed to have capacity for 18 or even 20, depending on the day.

A dose of a drinking religion was also served with each lunch and dinner: its only mandate was bottle-blindness. By the end of harvest, bottles wrapped their way around the harvest house, and except for the Champagne (treated as special and magic animal) everything we tasted was from a decanter: not even the shape of the bottle could be a clue to what we were drinking. Before each meal, Natalie or Luis would go to the box-strewn garage to pick two, three, or four bottles (lunch), or perhaps three, four, or five (dinner). And then, for a moment, the kitchen was secured like a military bunker. No living soul was permitted to enter while bottles were poured into decanter, until they were safely tucked away for a later reveal.

For all the practical and theoretical winery work, here at the table we received our education in what wine could be, and how to enjoy it. The vehicle for that education was the simplest blind-tasting game: taste the wine, discuss what you thought about the wine, and say what you thought it was — country, region, grape, and/or producer depending on your level of skill.

To see a wine correctly called with confidence seems like magic, but blind tasting is a numbers game, a pattern-matching exercise. You recognize the regions/grapes/producers you’re familiar with that the bottle is not. You recognize what you’re familiar with that the bottle might be. The activity, with every glass, builds up new sensitivity to how a wine expresses itself, raises questions about how and why it might be that way. And every tasting, so long as one can attend to and register the subtleties in the glass, augments the existing set of known patterns, opens up new surface area from the previously unknown.

It took weeks of calibration to speak to the bottles we opened with any justifiable confidence. It was frustrating, with repeated wrong calls so far off the mark as to be a joke. However — as always — care, effort, repetition, and attention bring learning: each week brought with it, for some wines, a sudden snap into place. The wines made sense and matched enough of what had come before to make themselves clear. We grew familiar with a briny acidity underneath the aromatics that marked Albariño from Rias Baixas, the high-toned-floral-and-hay-and-candy of Rabigato from the Douro Valley. We learned to find that freshly ground cinnamon-pepper-green of Galician Mencia that drove its red fruit. To feel for the roses and wild garlic that mark a Piemontese Nebbiolo. To catch the burnt-popcorn sulfur and reduction of Tenerife.

Burgundy, Vinho Verde, Chablis, Chinon, St. Joseph, Jura, Saumur, and Sicily. Morgon, Brouilly, Douro, Alentejo, Azores, Barolo, and Bierzo. Napa, Ribeiro, Tenerife, Alsace—everything was on the table. We tasted 360 bottles in six weeks, each added to the shrine wrapping around the base of our harvest house. And besides the clearly flawed and the brashly natural, the few unfinished bottles were the disproportionately expensive. The forced attention of blind tasting leads to learning, the attempt to register without seeing the label lets us understand what we really like: ignoring prestige, social pressure, and high-quality marketing campaigns.

Not that it always works. Serve a well-regarded producer’s bottle, blind, to your wine-loving friends. Watch the discussion, the subjective indicators of taste, see how people treat the wine. And then reveal the label. It doesn’t take long to see the positive and unconscious shift of opinion: “Ah, I love this wine.” “Yes, of course I thought it was good.” (Do you? Did you?) The subjective experience of taste quickly blends into the larger story of what the producer or the wine means to us — a tiny window into the complex interaction of perception, memory, and self-identity as they interact with contents of a bottle, or the image its label brings to bear.

It’s addictive, and perhaps annoying to those who haven’t been drinking blindly as a general rule. I have decanters to serve my friends, not because the wine needs decanting, but because it needs blinding. While few of my back-to-normal life lunches and dinners match the consistent quality of our harvest meals (or the quantity of accompanying wines,) the joy of good food and always-blind-bottles remains.

And we did take a few fast dinners, eat a few shorter lunches, during harvest. On the week of the storm, one night we only had beer, and another, we drank only water. Exceptions prove the rule.

We were running on a Portuguese translation of the old Zen proverb: “If you don’t have time to eat lunch for an hour, you should eat lunch for two hours.” In the six weeks of harvest, it was the joy of wine, food, and conversation at the table that held the team together through the depths of suffering. Work hard, but never let it stop you from sitting with friends, eating well. Drink blind, and speak, to learn and understand what’s in the glass, without preconception. When you’re cooking, wear an apron. At the table, the more the merrier. And — as always — don’t break the glass.

Epilogue: DH1 the Barrel

“Hey Luis."

"Yes, Dave."

"I want to age my wine in a used barrel.”

“That’s nice.”

“But I don’t have a barrel. Can I use one of yours?”

“I need every barrel I’ve got. And that’s already not enough.”

“Ahhhh. How do I get a good used barrel?”

“Well, that’s something every winemaker has to figure out.”

Luis offered harvest interns 25 boxes of grapes for making ‘our own wine,’ from an incoming vineyard of our choosing, so long as we did it after our primary work. António and I took him up on the offer. I pulled aside a pallet of boxes from a high-altitude red field blend, a vineyard 10 minutes’ walk from our harvest house.

The broad strokes of winemaking seem, in some way, terribly simple: work with good grapes, get them in a vessel, allow fermentation to run its course, keep the juice in a vessel to age, bottle, et voila. In reality, each step carries a range of decisions, options, tradeoffs, and details, requiring equipment and care. Thankfully, I don't yet know enough to be so worried about all that. I asked the team to help me with a small sorting table, got the grapes in a large plastic bin, and crushed the first 20 boxes underfoot while leaving 5 boxes of grapes fully intact (tucked underneath the juice line and crushed clusters). I sealed the grapes in with neutral gas under plastic wrap for a day of maceration, and then put light and loose-fitting plastic sheets on top to cover as fermentation started.

Every day, twice a day, I pressed down the grapes on top, keeping them wet, preventing mold, working gently to avoid heavy extraction. As we tasted the wine, the light level of work was not showing enough of the structure these Douro grapes had to offer. I increased the work, hand turning the grapes with more force each day, about 10 minutes morning and night. The structure of the wine got big, fast, with stemmier, rougher green tannin. I learned from Luis that a higher alcohol content at the end of fermentation increases the effectiveness of extraction from all that extra work (alcohol is a solvent.) It was certainly big enough to warrant time in neutral oak to bind the structure together, to soften it up.

But what about that barrel? Through multiple nights of dinner-table negotiation with a would-be benefactor, it was arranged that António and I would each get one 400-liter used red-wine barrel from Luis, and Luis would receive two used 500-liter barrels on loan for the duration. Antonio labeled his barrel A1. I labeled my barrel DH1. Baby’s first wine.

DH1 is aging in Luis’ cellar. Because barrels are porous, the wine evaporates a bit every day. The level of liquid drops, and the surface area exposed to air and oxygen increases, potentially leading to spoilage or oxidation. My barrel is being topped up with wine reserved in a stainless steel tank, on regular rotation with the rest of Luis’ barrels, and António’s A1 as well.

I’ve tasted it recently: it’s real, it’s certainly wine, it’s not bad, and I even think I like it. (How would that go if it was served blind?) Luis warns me each time we sample the barrel that, beyond the definition of structure, it’s hard to say how it will really unfold until this spring, when the cellar warms up and the wine comes out of its first cold slumber.

Seeing how Luis makes great wine was a necessity, and starting my own small batch, the beginning. But what does it take to make a great wine? To work an agriculture I can be proud of? And to see my own winemaking bring out the best in those grapes? The only way forward is to try. Conscious effort, repetition, experimentation, careful attention: allowing, one hopes, the little details to snap into place, to make sense up and down that interwoven cascade of choices that begin with the vine and end with something remarkable in the bottle.